Overview

Who We Are

Founded in 1984, Data Spectrum has excelled in developing industrial, scientific, and medical products for OEM clients. Our expertise spans imaging, motion control, avionics, and medical electronics, offering solid engineering experience and comprehensive services from circuit design to mechanical modeling. We tackle medical product design and regulatory compliance, delivering successful projects showcased on our website.

Headquarters

Located at 19160 Van Ness Ave Torrance, CA 90501, Data Spectrum is your reliable partner for innovative engineering solutions.

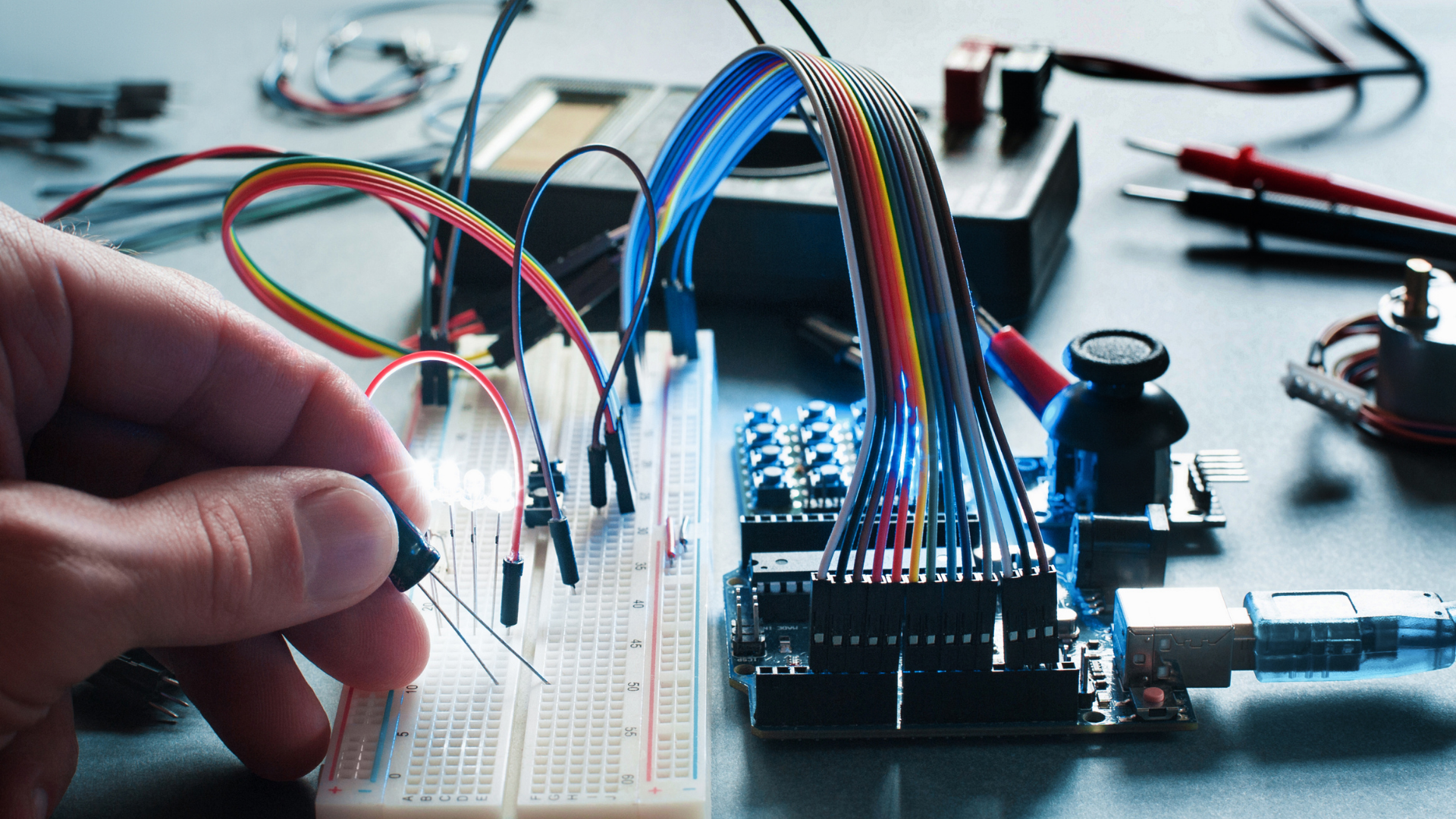

Manufacturing

Our full service abilities include circuit design, PCB layout & fabrication, and mechanical design & 3D modeling. Since we define and manage the interface details between software, electrical and mechanical packaging, your product will come to life with the fewest iterations.

With our experience in medical product design, we can handle the added challenges of getting technical products to market within the constraints of regulatory review and product safety and reliability considerations.

Boost Your Engineering Department's Output

At Data Spectrum, Inc., we specialize in innovative and reliable engineering solutions.

Our extensive experience in consulting and product development allows us to seamlessly integrate with your team, filling skill and technology gaps. We accelerate your technical product development, ensuring smooth progress and successful outcomes even during manpower shortages or schedule challenges.

Let us enhance your capabilities and drive your projects to new heights.